Filterpressenpumpen für präzise Filtration in jeder Anwendung

In nahezu jedem Industriezweig kommt es zu unnötigen Abfallstoffen und Abwässern. Um diese unerwünschten Substanzen effizient zu separieren, werden Filterpressen eingesetzt, die mithilfe von Filterkuchen die gewünschte Trennung ermöglichen. Ein entscheidender Faktor in diesem Prozess sind die speziellen Filterpressenpumpen, die für das präzise Befüllen von Kammerfilterpressen und Filterpressen verantwortlich sind.

Bei STEINLE bieten wir hochwertige Filterpressenpumpen an, die auf die Anforderungen verschiedenster Anwendungen, einschließlich Kammerfilterpressen, zugeschnitten sind.

Funktionsweise von Filterpressen

Die Funktionsweise von Filterpressen unterscheidet sich im Vergleich zu elektrischen Pumpen. Zu Beginn des Pressvorgangs ist die Filterpresse noch leer, wodurch das Produkt leicht hindurchfließen kann. In diesem Stadium ist der erforderliche Druckbereich sehr niedrig. Mit fortschreitender Befüllung der Presse steigt jedoch kontinuierlich der Druck, den die Pumpe aufbringen muss. Für diesen Prozess eignen sich besonders gut druckvariable Pumpen, wie unsere druckluftbetriebenen Filterpressenpumpen.

Der entscheidende Vorteil im Vergleich zu elektrischen Pumpen liegt in der einfachen Steuerung und Funktionsweise unserer druckluftbetriebenen Filterpressenpumpen. Sobald der Druck in der Druckleitung den Luftdruck übersteigt, mit dem die Pumpe betrieben wird, stoppt die Pumpe automatisch, ohne Schaden zu nehmen. Zudem reguliert sich die Pumpe selbst. Dies führt dazu, dass die Fördermenge zu Beginn der Beschickung sehr hoch ist und mit zunehmendem Druck stetig abnimmt. Dadurch sinkt auch kontinuierlich der Luftverbrauch während des gesamten Pressvorgangs.

Die Anpassungsfähigkeit und Selbstregulierung unserer druckluftbetriebenen Filterpressenpumpen machen sie zu einer effizienten Lösung für Filterpressenanwendungen. Die einfache Handhabung, kombiniert mit geringem Energieverbrauch, trägt dazu bei, den Pressvorgang effektiv zu steuern und gleichzeitig Ressourcen zu schonen.

Vertrauen Sie auf die innovativen Lösungen von Steinle für einen reibungslosen Ablauf Ihrer Filterprozesse.

Was zeichnet Filterpressenpumpen von Steinle aus?

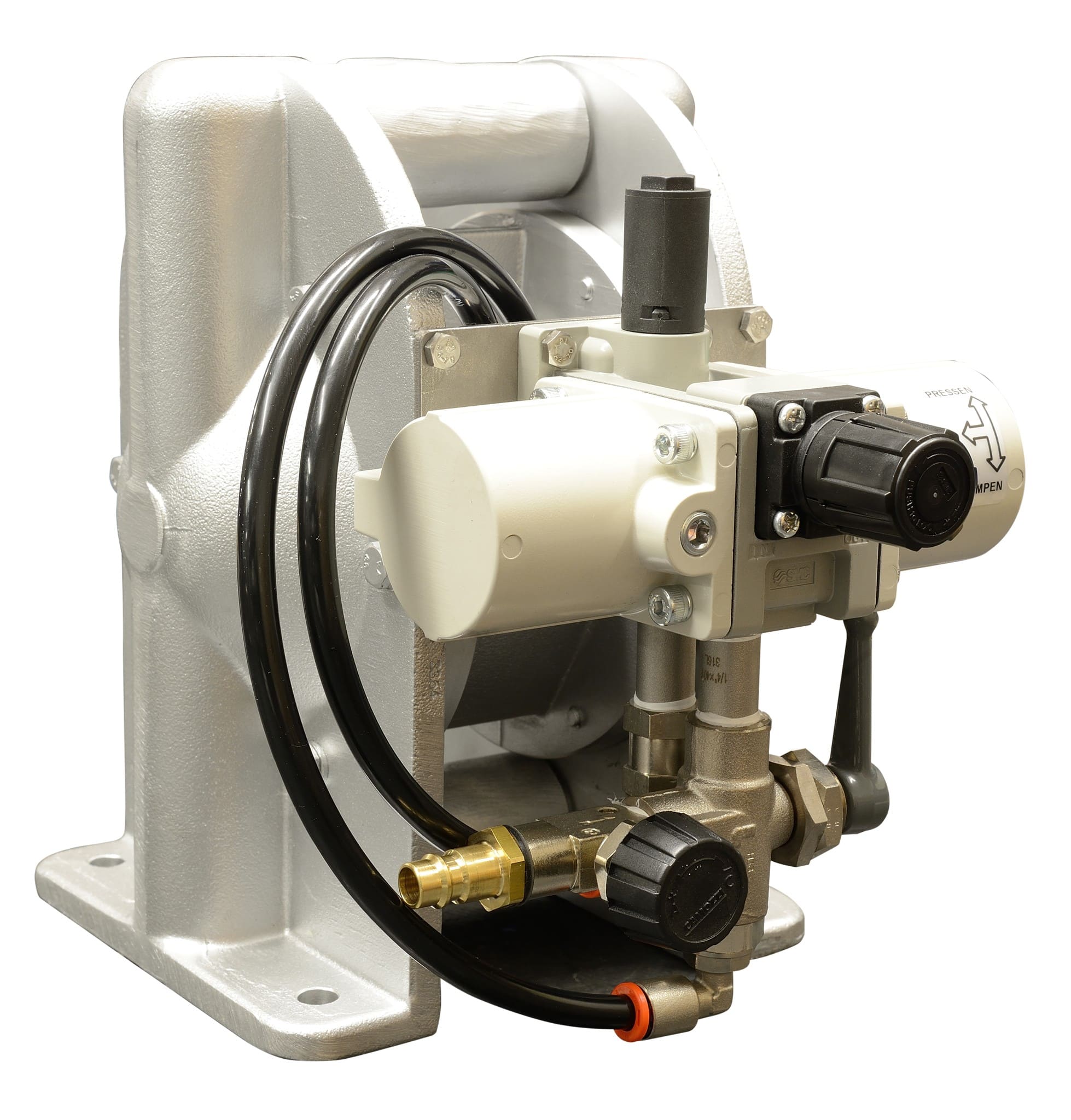

Unsere Filterpressenpumpen zeichnen sich durch ihre Robustheit, Zuverlässigkeit und hohe Leistungsfähigkeit aus. Sie spielen eine Schlüsselrolle in der Gewährleistung eines reibungslosen Betriebs der Kammerfilterpresse, indem sie das zu filtrierende Produkt mit präziser Dosierung in die Presse fördern. Durch modernste Technologien und sorgfältige Fertigung gewährleisten wir, dass unsere Pumpen den anspruchsvollen Anforderungen der Industrie gerecht werden.

Optimierte Filtertechnologie: Druckkonstanz für zuverlässige Filtration

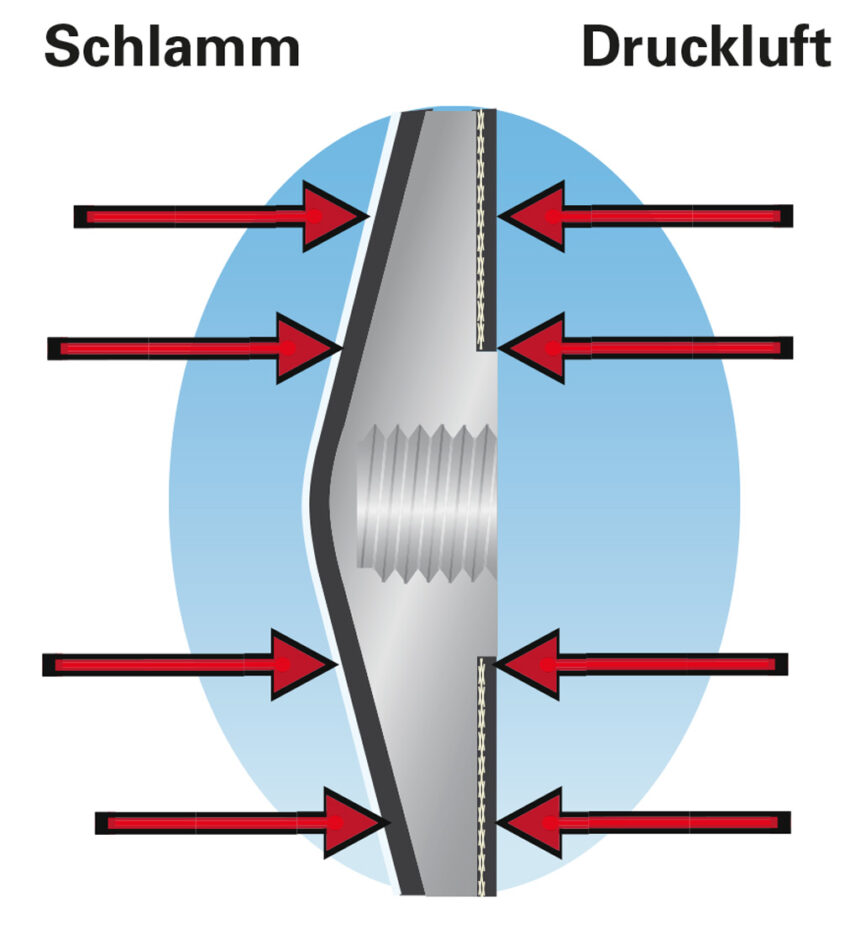

Dadurch, dass die Druckluft schon komprimiert in die Pumpe strömt, wird die Membran vollflächig mit dem gleichen Druck beaufschlagt, wie er auch auf der Schlammseite herrscht. Somit hat die Membran keine Druckdifferenz auszuhalten, was ihre lange Lebensdauer erklärt. Diese Eigenschaft ermöglicht auch den Einsatz von Standardmembranen aus verschiedenen Werkstoffen. Bei vielen anderen druckluftbetriebenen Filterpressenpumpen wird dagegen nur die Hälfte des Drucks hinter den Membranen aufgebaut, die andere Hälfte wird über die Kolbenstange aufgebracht. Der Druck auf beiden Seiten der Membran bleibt dabei stets konstant.

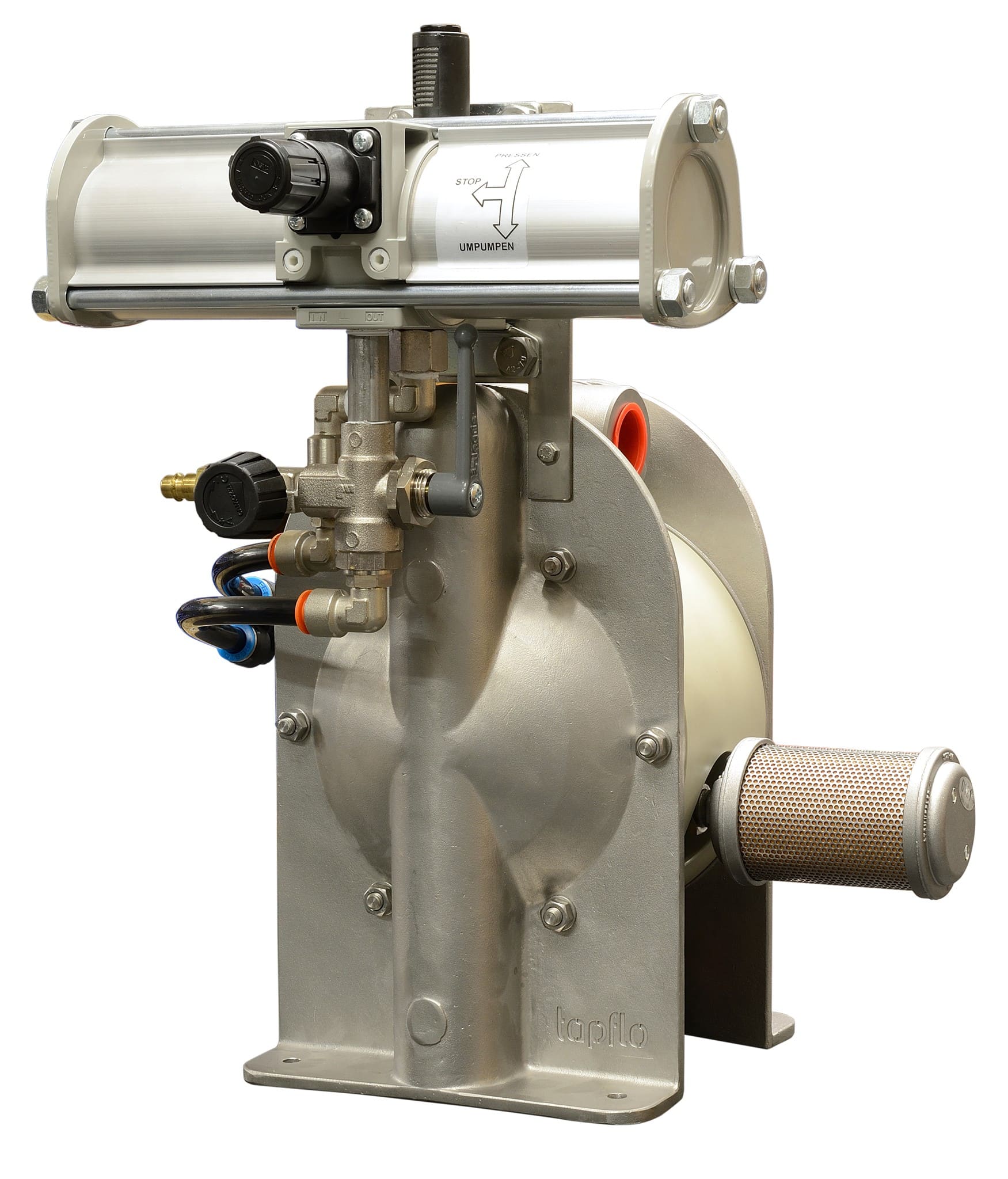

Maximale Effizienz: Eco-Boost-Funktion für Filterpressenpumpen mit externer Druckübersetzung

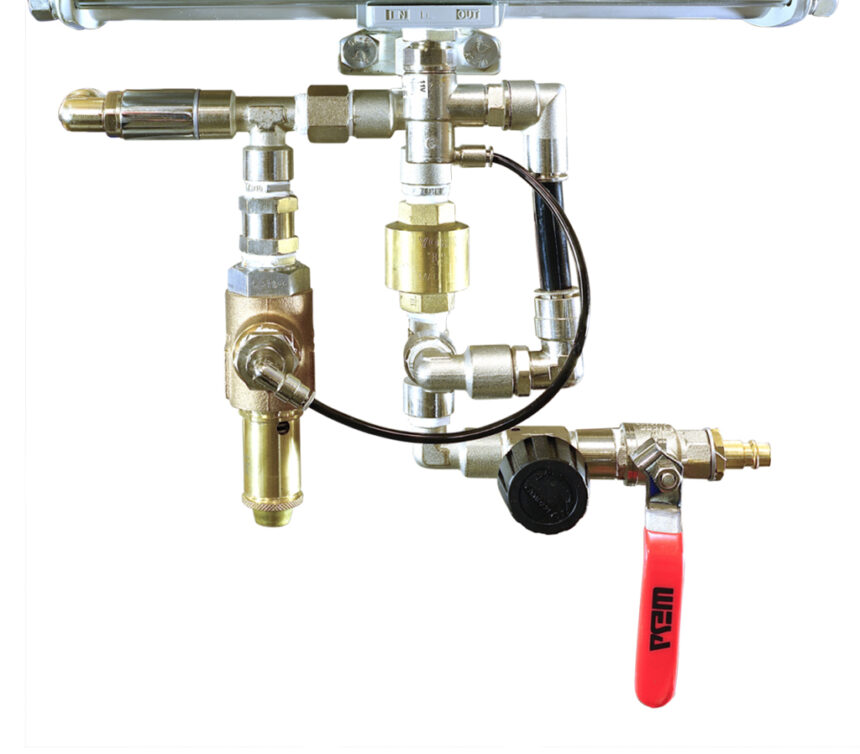

Alle Pumpen verfügen über die Möglichkeit, nahtlos von der „Pumpen“- auf die „Pressen“-Funktion umzuschalten. Im „Pumpen“-Modus wird der Druckverstärker der Pumpe umgangen und die Druckluft strömt direkt in die Pumpe. Diese Funktion spart Druckluft beim Füllen der Filterpresse sowie Kammerfilterpresse und schont den Druckverstärker. Diese Schaltung ist auch vollautomatisch verfügbar, siehe Eco-Boost. Beachten Sie bitte, dass diese Funktion nur bei Pumpen mit externer Druckübersetzung verfügbar ist!

Eco-Boost-System zur Energieeinsparung

Automatische Druckerhöhung für pneumatische Filterpressenpumpen der Baureihe TF

Alle Pumpen verfügen über die Möglichkeit, nahtlos von der „Pumpen“- auf die „Pressen“-Funktion umzuschalten. Im „Pumpen“-Modus wird der Druckverstärker der Pumpe umgangen und die Druckluft strömt direkt in die Pumpe. Diese Funktion spart Druckluft beim Füllen der Filterpresse sowie Kammerfilterpresse und schont den Druckverstärker. Diese Schaltung ist auch vollautomatisch verfügbar, siehe Eco-Boost. Beachten Sie bitte, dass diese Funktion nur bei Pumpen mit externer Druckübersetzung verfügbar ist!

Bis zu 35 % Drucklufteinsparung: Eco-Boost als optionale Erweiterung

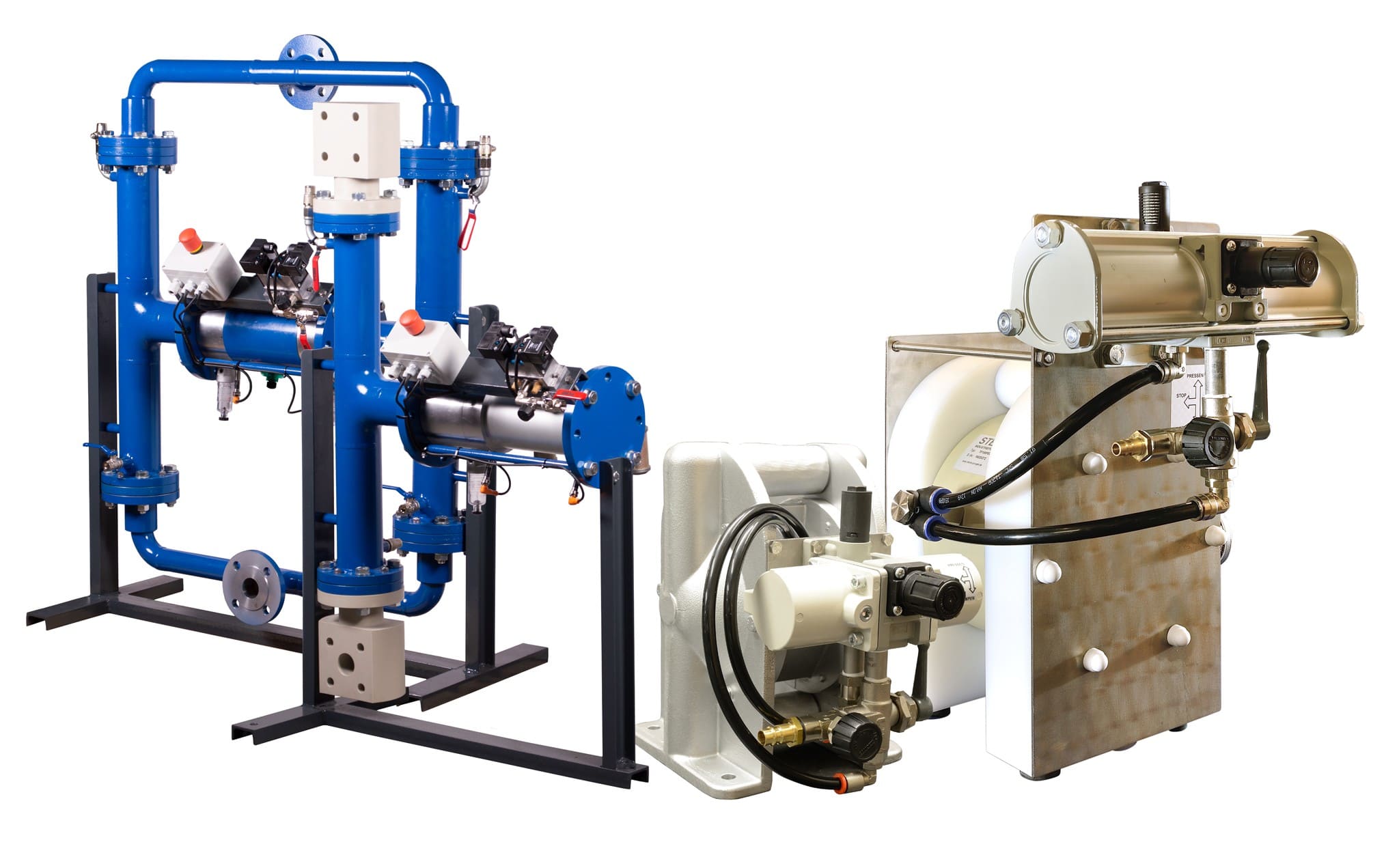

Für diese Fälle wurde das Eco-Boost-System entwickelt. Dieses System arbeitet ausschließlich pneumatisch und verzichtet auf elektrische Steuerkomponenten. Ab einem bestimmten Druck in der Filterpresse schaltet sich der externe Druckverstärker automatisch ein und übernimmt die Förderung in der Hochdruckphase. Das Eco-Boost-System ist in drei verschiedenen Baugrößen als optionale Erweiterung für alle Pumpen der Baureihe TF erhältlich. Zudem kann es auch bei bestehenden Pumpen mit externer Druckübersetzung problemlos nachgerüstet werden.

Wann ist der Einsatz einer TF-Pumpe sinnvoll und wann sollte man auf eine FP/FH-Pumpe zurückgreifen?

TF-Pumpe

Die TF-Pumpe ist eine ideale Wahl unter den folgenden Bedingungen:

- Druckübersetzung 1:2

- leicht abrasive Medien

- geringe Investitionskosten

- geringer Platzbedarf

- einfache Hydroxidschlämme

Die TF-Pumpe zeichnet sich durch ihre Effizienz und Wirtschaftlichkeit aus und eignet sich besonders für Anwendungen, die eine zuverlässige Förderung bei geringem finanziellen Aufwand erfordern.

FP/FH-Pumpe

Die FP/FH-Pumpe hingegen zeigt ihre Stärken in den folgenden Szenarien:

- hohe Druckübersetzung bis zu 1:3,3

- stark abrasive Medien

- höhere Investitionskosten

- hoher Platzbedarf

- kritische Schlämme

Die FP/FH-Pumpe bietet eine robuste Lösung für anspruchsvolle Anwendungen, bei denen hohe Druckanforderungen und der Umgang mit abrasiven oder kritischen Medien im Vordergrund stehen. Die Investition in diese Pumpe zahlt sich durch ihre Leistungsfähigkeit und Zuverlässigkeit aus, besonders in Umgebungen mit anspruchsvollen Förderanforderungen.

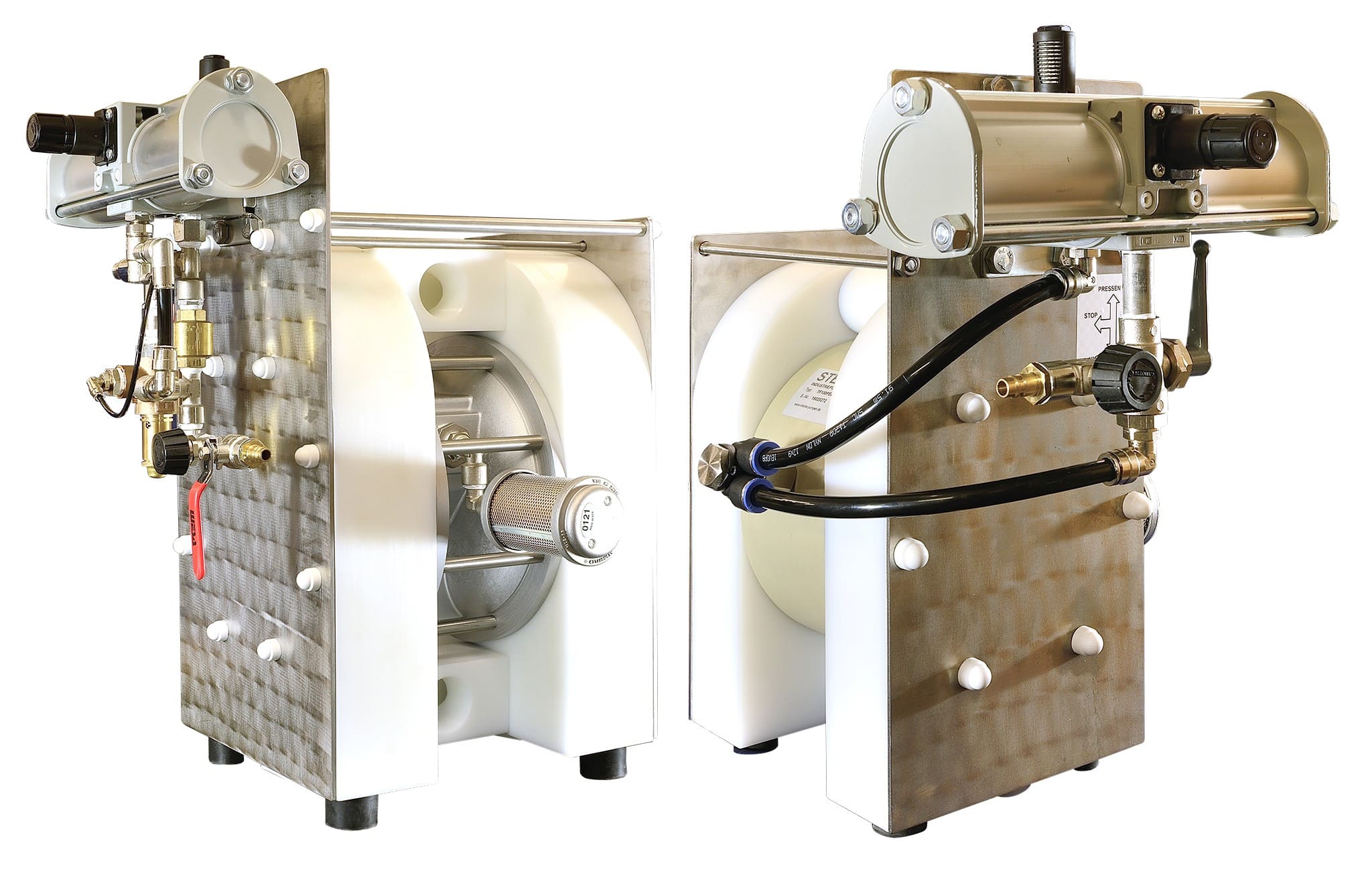

Unser Filterpressenpumpen im Überblick

Schicken Sie uns eine unverbindliche Anfrage

Interessieren Sie sich für unsere Filterpressenpumpen oder haben Sie offene Fragen?

Gerne beraten wir Sie persönlich zu unseren Pumpenlösungen für Ihren individuellen Anwendungsfall.